Welcome To Know Our Products, We Can Offer You High Quality Products!

WhatsApp : +8617736177359

Email : sales@fqcarbon.com

Process flow

Provide customers with high-quality products and services

1.

The Raw Material Crushing

The high quality needle coke or petroleum coke broken by mechanical equipments to particle size in accordance with process requirements after self-calcination.

2.

Dosing & Kneading

Needle coke is crushed in mechanical equipment, screening, and then the dosing is according to the proportion of ingredients required by the formula. The sifted raw material particles are mixed with a certain proportion asphalt according to the formula and stirred into the paste with a certain plasticity by heating.

3.

Extrusion Forming

Put the paste with suitable temperature into the forming machine, pressure extrusion, form green-pressing with different sizes.

4.

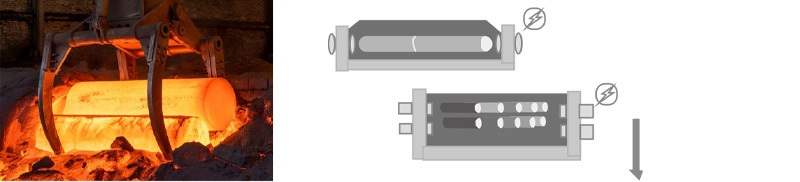

The First Baking

In the baking furnace, the green-pressing electrode is baked with a certain temperature according to the process requirements.

5.

High Pressure Impregnation

The baked products, are treated through vacuum and high pressure with special asphalt, in order to be more compact.

6.

The Second Baking

The products after impregnation are baked again through the tunnel kilns, to make asphalt coking fully, to improve the density and strength of the products.

7.

Graphitization

The products after baking are put into graphitization furnace with temperature above 3000 ° C, which rearrange the carbon atoms into specific graphite crystals.

8.

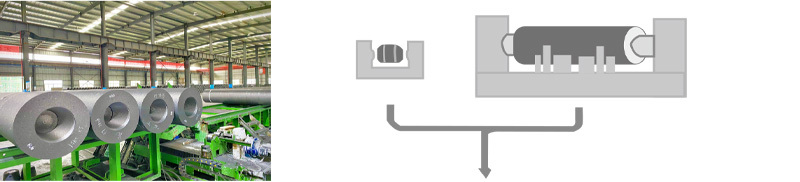

Machining

The products, after been graphitized, are machined into graphite electrodes which meet the requirements of dimensional accuracy.

9.

Quality Inspection

The finished products are inspected in specifications and machining precision.

10.

Packaging & Shipment

Qualified graphite electrodes are packaged according to clients’ requirements and delivered to customers by vessel, train or truck.