Welcome To Know Our Products, We Can Offer You High Quality Products!

WhatsApp : +8617736177359

Email : sales@fqcarbon.com

Process flow of graphite electrode

2023-05-05

Raw materials: What are the raw materials used in carbon production?

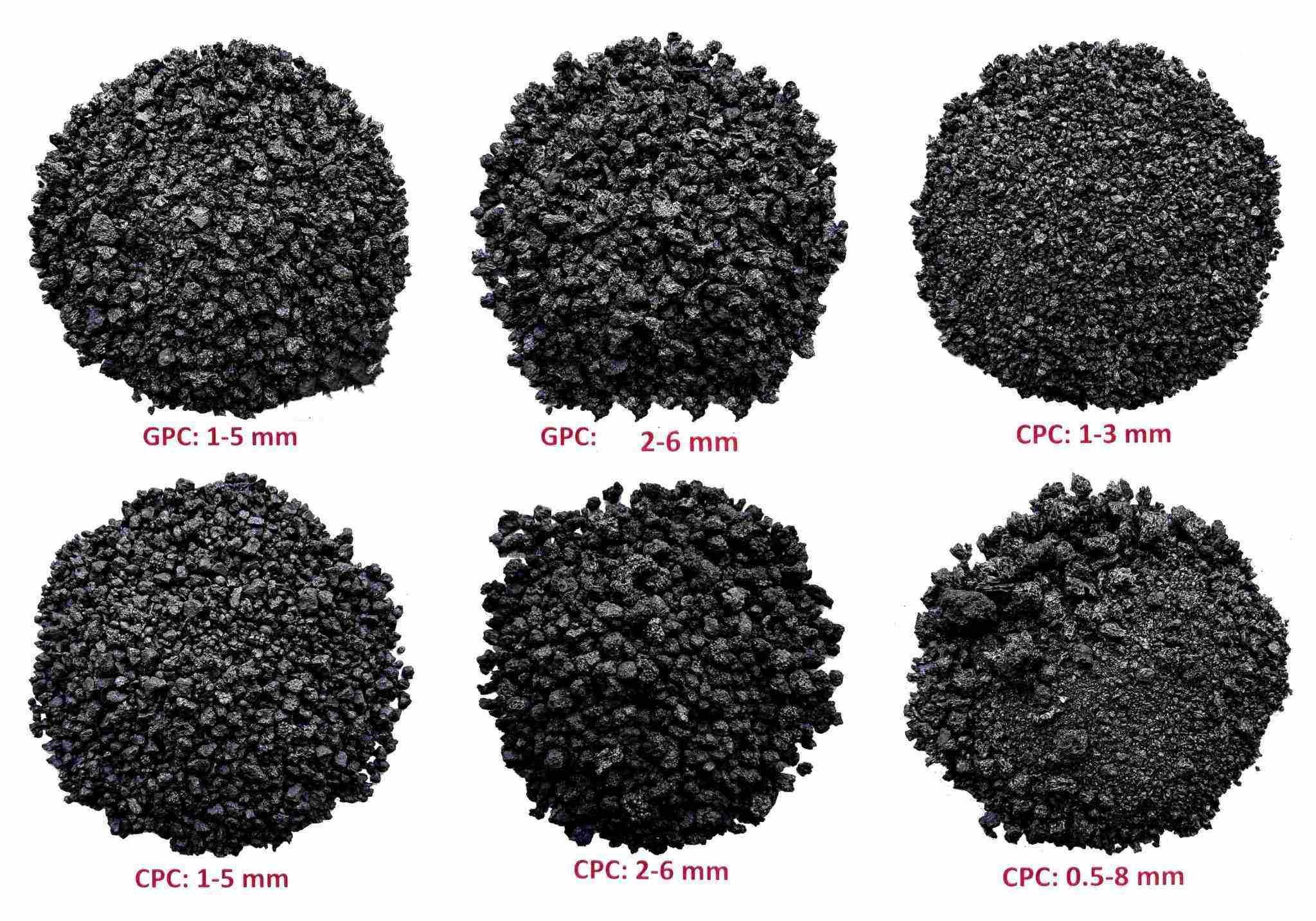

In the production of carbon, the commonly used raw materials can be divided into two categories: solid carbon raw materials, binders and impregnators. Solid carbon raw materials include petroleum coke, pitch coke, metallurgical coke, anthracite, natural graphite and graphite crushing, binders and impregnators include coal tar pitch, coal tar, anthracene oil and synthetic resins. In addition, in the production also used quartz sand, metallurgical coke powder, coke powder and other auxiliary materials. Other special raw materials are used to produce some special carbon and graphite products (such as carbon fiber, activated carbon, pyrolytic carbon and pyrolytic graphite, glass carbon).

Calcination: What is calcination? What raw materials need to be calcined?

The process of heat treating carbon raw materials at high temperature (1200≤1500°C) under isolated air conditions is called calcination. Calcination is the first heat treatment process in carbon production. Calcination causes a series of changes in the structure and physical and chemical properties of various carbon-containing raw materials.

Both anthracite and petroleum coke contain a certain amount of volatiles and need to be calcined. The coking temperature of asphaltene coke and metallurgical coke is relatively high (above 1000℃), which is equivalent to the temperature of the calciner in the carbonization plant. It can no longer be calcined and only needs dry moisture. However, if asphalt coke and petroleum coke are mixed before calcining, they should be sent to the calciner together with petroleum coke. Natural graphite and carbon black do not require calcination.

Stamping: What is the principle of extrusion forming?

The essence of the extrusion process is to make the paste through a certain shape of the die, through compaction and plastic deformation, to form a certain shape and size of the wool embryo. The extrusion process is mainly the plastic deformation process of the paste.

graphite electrode

RELEVANT INFORMATION