Welcome To Know Our Products, We Can Offer You High Quality Products!

WhatsApp : +8617736177359

Email : sales@fqcarbon.com

The Interplay Between Petroleum Coke and Graphite Electrodes

2023-09-04

Petroleum coke and graphite electrodes are two integral components in the realm of metallurgy, particularly in electric arc furnace (EAF) steelmaking and aluminum production. While seemingly distinct, their relationship is profound, as petroleum coke serves as the primary raw material for the production of graphite electrodes. This article explores the intricate connection between petroleum coke and graphite electrodes, shedding light on their significance in various industrial processes.

Petroleum Coke: An Essential Precursor

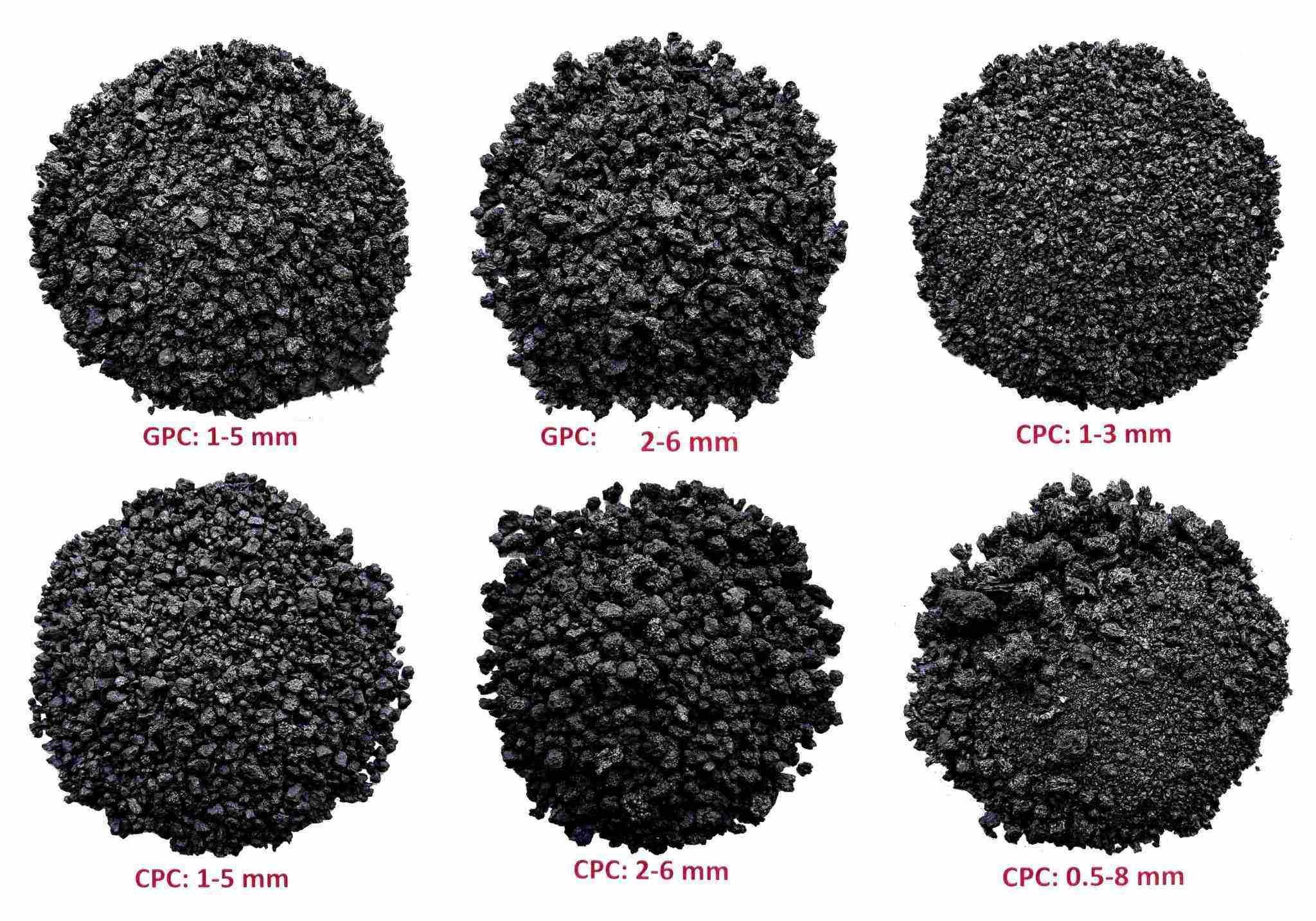

Petroleum coke, often referred to as petcoke, is a carbonaceous solid derived from the distillation of crude oil. It is primarily composed of carbon, along with small amounts of sulfur, nitrogen, and other impurities. Petcoke is notable for its high carbon content, making it an ideal precursor material for the production of graphite electrodes.

The Manufacturing Process

The journey from petcoke to graphite electrode involves a series of intricate steps. First, petroleum coke is calcined at high temperatures, typically exceeding 1300°C, to remove volatile compounds and impurities. This calcined coke is then mixed with pitch, a binder material derived from coal tar distillation. The mixture is then extruded and molded into the desired electrode shape, followed by baking at elevated temperatures in a controlled environment. The final step involves graphitization, where the baked electrodes are subjected to even higher temperatures (above 2500°C) in the presence of a catalyst, transforming them into graphite electrodes.

Graphite Electrodes: The Crucial Components

Graphite electrodes are crucial components in various high-temperature industrial processes, such as EAF steelmaking and aluminum smelting. They serve as conductive elements in electric arc furnaces, where they transmit electrical energy to the charged materials, causing them to melt and react. Graphite electrodes are highly desirable due to their exceptional electrical conductivity, high melting point, and chemical stability in extreme conditions.

The Role of Graphite Electrodes

In electric arc furnace steelmaking, graphite electrodes are immersed into the furnace and connected to a power source. When an electrical current is passed through the electrodes, it creates a high-temperature arc between the electrode tip and the raw materials (typically scrap steel or iron ore). This intense heat melts the materials, facilitating chemical reactions and ultimately leading to the production of molten steel.

Similarly, in aluminum smelting, graphite electrodes are used to electrolytically reduce alumina (Al2O3) into aluminum metal. The high electrical conductivity and thermal stability of graphite electrodes make them indispensable in this energy-intensive process.

Conclusion

In conclusion, the relationship between petroleum coke and graphite electrodes is essential in several key industrial processes. Petroleum coke, through a series of refining and manufacturing steps, serves as the primary precursor material for the production of high-quality graphite electrodes. These electrodes, in turn, play a pivotal role in electric arc furnace steelmaking and aluminum smelting by facilitating the conversion of raw materials into valuable metals. Understanding this intricate interplay between petroleum coke and graphite electrodes highlights the critical importance of both materials in modern metallurgical industries, ensuring the continued production of high-quality steel and aluminum products worldwide.

GPC ,Graphite Electrode

RELEVANT INFORMATION