Welcome To Know Our Products, We Can Offer You High Quality Products!

WhatsApp : +8617736177359

Email : sales@fqcarbon.com

Manufacturing Process and Applications of RP, HP, and UHP Graphite Electrodes

2023-10-09

Manufacturing Process and Applications of RP, HP, and UHP Graphite Electrodes

Graphite electrodes, including RP (Regular Power), HP (High Power), and UHP (Ultra High Power), are essential components in electric arc furnaces used for various metallurgical processes. This article will outline the manufacturing process of these electrodes and their applications in different industries.

Manufacturing Process:

-

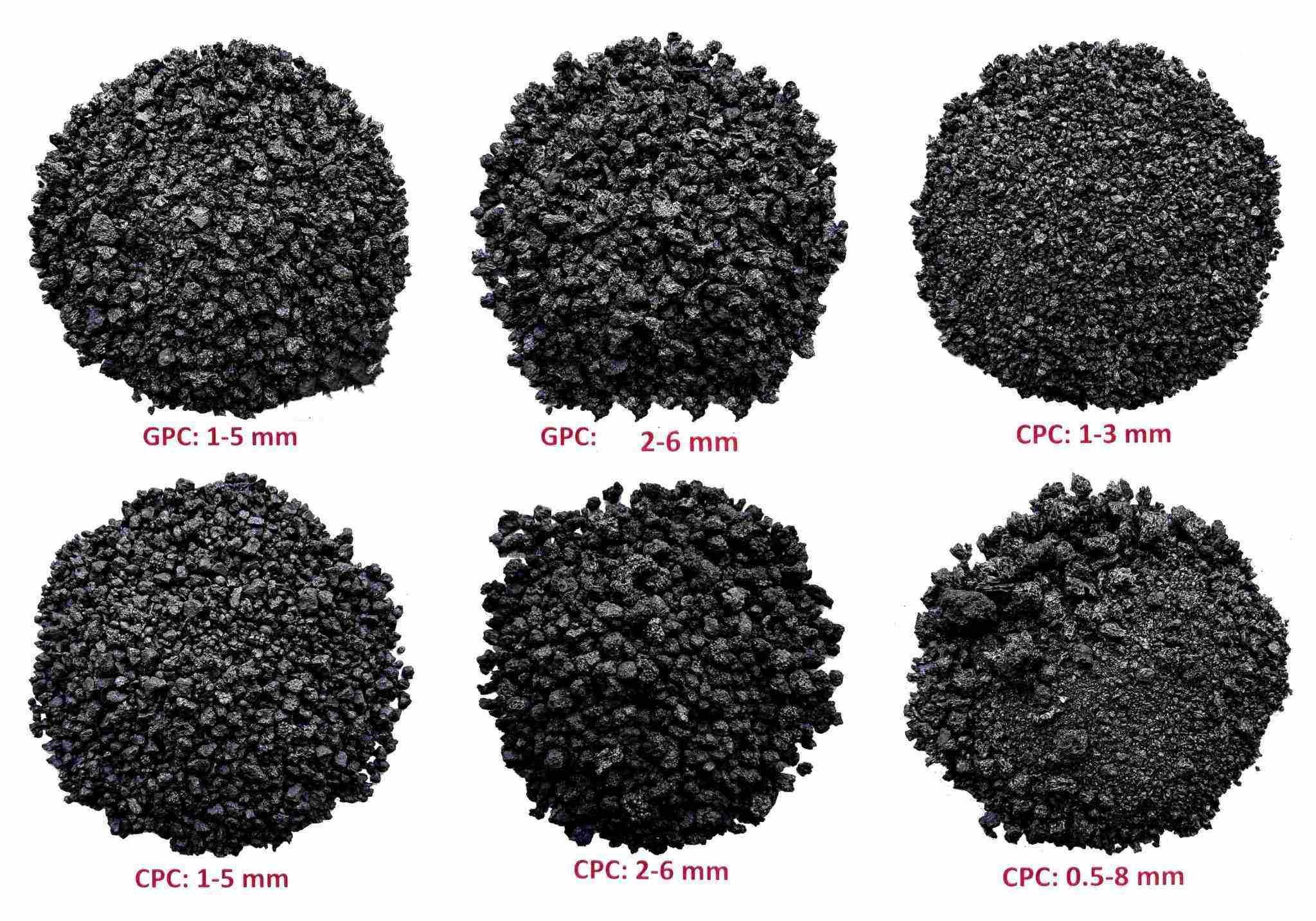

Raw Material Selection: The manufacturing process begins with the careful selection of high-quality petroleum coke and coal tar pitch. These materials are chosen for their purity and carbon content, as they significantly impact the final properties of the graphite electrodes.

-

Mixing and Batching: The selected raw materials are mixed and batched in precise proportions. This mixture is heated to form a homogenous blend, ensuring consistent quality.

-

Extrusion: The blended material is then extruded through molds to create the desired electrode shape and size. This process is critical for achieving the electrode's structural integrity.

-

Baking: The green electrodes are baked in specially designed ovens at high temperatures to remove impurities and volatile components. This process, known as calcination, transforms the green electrodes into hard and stable carbon structures.

-

Graphitization: The baked electrodes are subjected to a second heat treatment called graphitization. This process elevates the carbon content, improves electrical conductivity, and enhances the mechanical strength of the electrodes.

-

Machining and Quality Control: After graphitization, the electrodes undergo machining processes to meet precise dimensional tolerances and surface finish requirements. Rigorous quality control checks are performed to ensure the electrodes meet industry standards.

-

Nipple Attachment: Nipples made of high-quality needle coke are attached to one end of the electrodes. This step is crucial for connecting the electrodes to the electric arc furnace.

-

Final Inspection: Each electrode undergoes a final inspection to verify its physical and electrical properties. This includes checks for density, resistivity, thermal expansion, and other critical parameters.

Applications:

-

Steel Production: Graphite electrodes are primarily used in electric arc furnaces for steel production. UHP electrodes are preferred for this application due to their excellent thermal and electrical conductivity, allowing for efficient melting and refining of steel.

-

Non-Ferrous Metal Smelting: HP and UHP graphite electrodes find applications in non-ferrous metal smelting processes, such as aluminum and copper production, where high-temperature conditions and precise control of the melting process are essential.

-

Chemical Industry: In the chemical industry, graphite electrodes are employed in the production of various chemicals and materials through processes like electric arc furnace reduction and electrolysis.

-

Glass Manufacturing: RP and HP electrodes are used in glass manufacturing to melt raw materials and create glass products of different compositions.

-

Electrical Discharge Machining (EDM): RP and HP electrodes are utilized in EDM for precision machining of metals and other conductive materials.

In conclusion, RP, HP, and UHP graphite electrodes play a vital role in numerous industrial processes, ranging from steelmaking to chemical production. Their quality and properties are carefully controlled throughout the manufacturing process to ensure optimal performance in their respective applications.

RELEVANT INFORMATION