Welcome To Know Our Products, We Can Offer You High Quality Products!

WhatsApp : +8617736177359

Email : sales@fqcarbon.com

Graphitized Petroleum Coke (GPC) and Calcined Petroleum Coke (CPC) are two distinct

2023-10-11

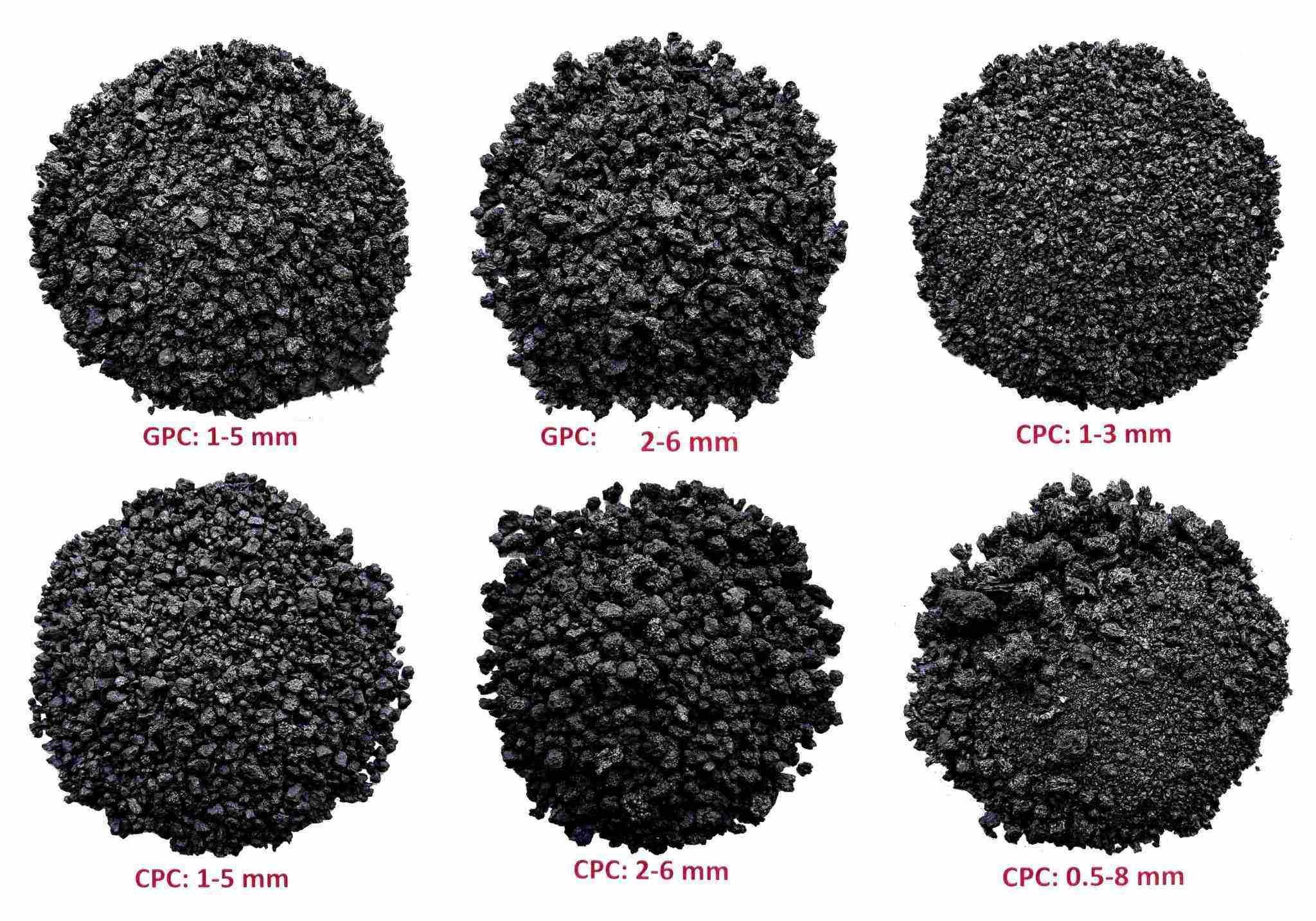

Graphitized Petroleum Coke (GPC) and Calcined Petroleum Coke (CPC) are two distinct carbon materials used in various industrial applications. These materials differ significantly in terms of their production process, properties, and applications. Let's explore the differences between GPC and CPC.

-

Production Process:

- GPC: Graphitized Petroleum Coke is produced by heating petroleum coke to extremely high temperatures (around 2800°C) in the presence of a catalyst. This process graphitizes the carbon structure, transforming it into a highly crystalline form.

- CPC: Calcined Petroleum Coke is made by heating green or raw petroleum coke to temperatures as high as 1500°C. This process removes moisture, volatile matter, and impurities, but it does not induce significant graphitization.

-

Crystalline Structure:

- GPC: GPC exhibits a highly graphitic crystalline structure. The carbon atoms are arranged in an ordered manner, similar to graphite, with well-defined hexagonal layers. This results in improved electrical and thermal conductivity.

- CPC: CPC has a less graphitic, more amorphous structure. It lacks the high degree of graphitization seen in GPC, which makes it less conductive and less suitable for applications where superior electrical and thermal properties are required.

-

Properties and Applications:

- GPC: Graphitized Petroleum Coke is primarily used in applications demanding high electrical conductivity, such as in the production of carbon electrodes for the steel and aluminum industries, as well as in the manufacture of lithium-ion batteries and fuel cells.

- CPC: Calcined Petroleum Coke, due to its lower graphitization, is used in applications where electrical and thermal conductivity are not the primary concerns. It is commonly used as a carbon additive in the production of anodes for aluminum smelting and as a raw material in the manufacturing of various carbon and graphite products.

In summary, GPC and CPC differ in terms of their production processes, crystalline structures, and applications. GPC is preferred when high electrical conductivity and graphitic properties are essential, while CPC is suitable for applications where these characteristics are less critical.

GPC ,CPC

RELEVANT INFORMATION