Welcome To Know Our Products, We Can Offer You High Quality Products!

WhatsApp : +8617736177359

Email : sales@fqcarbon.com

Exploring the Role of Graphite Electrodes in Energy Storage and Beyond

2023-08-31

Title: Exploring the Role of Graphite Electrodes in Energy Storage and Beyond

Subtitle: Unveiling the Remarkable Properties and Applications of Graphite Electrodes

Graphite electrodes have emerged as a critical component in various industries, offering a multitude of applications ranging from energy storage systems to metallurgical processes. Their exceptional conductivity, thermal stability, and mechanical strength make them an indispensable tool in modern technology. This article delves into the fascinating world of graphite electrodes, uncovering their properties, manufacturing process, and wide-ranging applications.

Understanding Graphite Electrodes

Graphite electrodes are highly conductive rods used in electric arc furnaces for the production of steel, where they facilitate the melting of raw materials through intense heat generation. These electrodes are made from high-quality graphite, a crystalline form of carbon known for its remarkable electrical conductivity. The structure of graphite, comprising hexagonal layers of carbon atoms, allows for the efficient movement of electrons, making it an ideal material for conducting electricity.

Properties that Set Graphite Electrodes Apart

-

Electrical Conductivity: Graphite electrodes possess exceptional electrical conductivity due to the arrangement of carbon atoms in their lattice structure. This property enables efficient energy transfer in various applications.

-

Thermal Stability: The high melting point of graphite, coupled with its ability to withstand extreme temperatures and thermal shocks, makes it a reliable choice for applications involving high heat.

-

Mechanical Strength: Graphite's layered structure grants it impressive mechanical strength and resistance to deformation, ensuring longevity and stability in demanding environments.

-

Chemical Inertness: Graphite electrodes exhibit resistance to chemical reactions, enabling their use in corrosive environments without significant degradation.

The Manufacturing Process

The production of graphite electrodes involves several intricate steps:

-

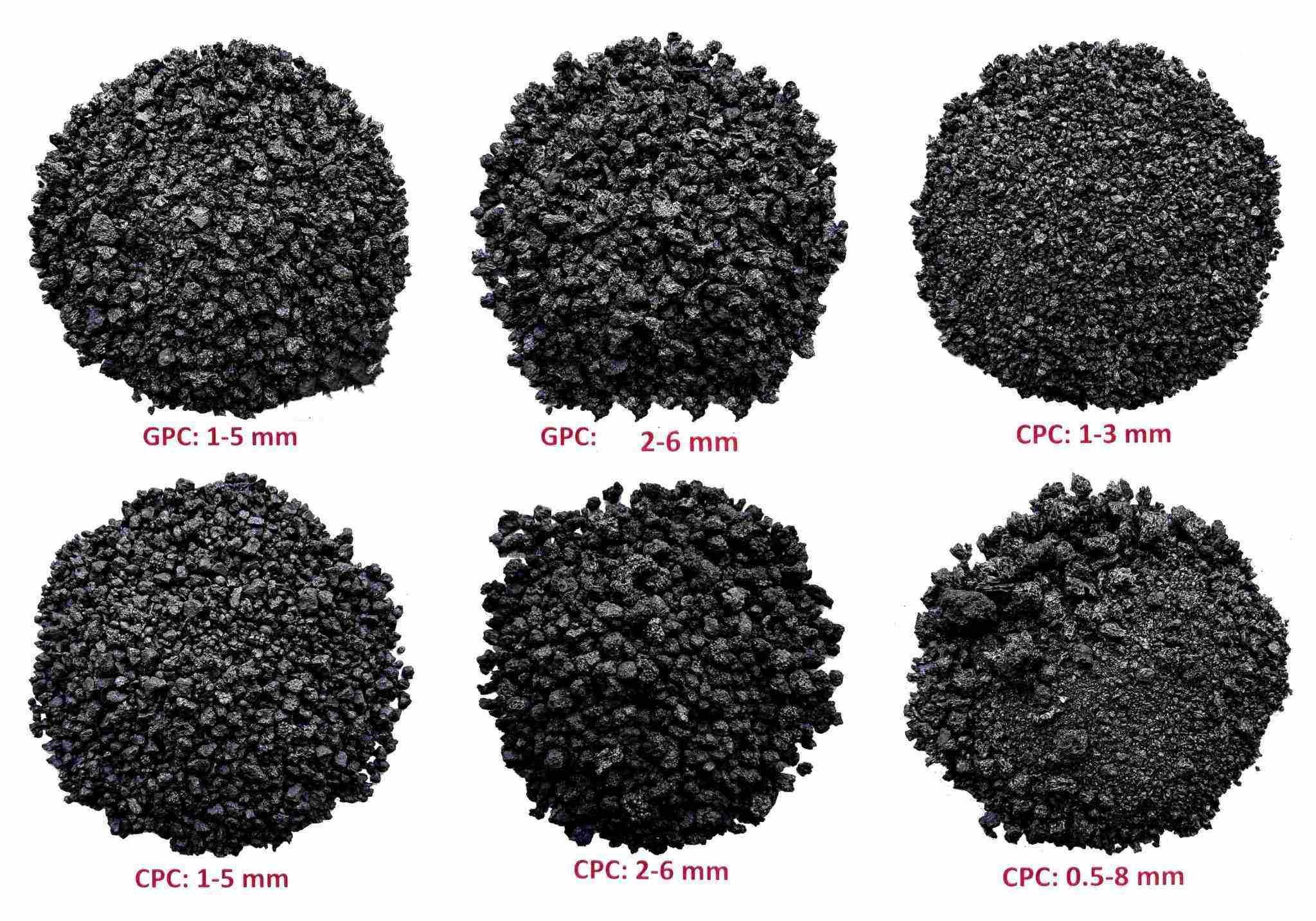

Material Selection: High-quality petroleum coke and needle coke are carefully chosen as the primary raw materials due to their low impurity content and desirable characteristics.

-

Mixing and Shaping: The chosen coke is ground into a fine powder and mixed with a binder pitch. The resulting mixture is then molded into the desired electrode shape.

-

Baking: The molded electrodes undergo a baking process in which they are heated to high temperatures in an oxygen-deprived environment. This process removes volatile components and strengthens the material's structure.

-

Graphitization: Baked electrodes are subjected to even higher temperatures in a controlled atmosphere to induce graphitization, where the carbon atoms rearrange into the characteristic hexagonal lattice structure, enhancing electrical conductivity.

-

Finishing: Electrodes are machined to precise dimensions, ensuring compatibility with various applications.

RELEVANT INFORMATION