Welcome To Know Our Products, We Can Offer You High Quality Products!

WhatsApp : +8617736177359

Email : sales@fqcarbon.com

Graphite Electrodes: Enabling Innovation and Advancement

2023-08-31

Graphite electrodes have emerged as a pivotal component revolutionizing industries with their exceptional properties and versatile applications. This article delves into the world of graphite electrodes, exploring their unique characteristics, manufacturing process, and diverse uses.

The Power of Graphite Electrodes

Graphite electrodes, known for their remarkable electrical conductivity and thermal stability, are sparking innovation across multiple domains. Their distinct properties make them indispensable for various applications.

Versatility in Properties

-

Electrical Conductivity: Graphite electrodes' lattice structure enables the efficient flow of electrons, making them a preferred choice in electrical applications demanding high conductivity.

-

Thermal Resistance: Withstanding extreme temperatures, graphite electrodes find utility in applications requiring heat generation or dissipation, enhancing efficiency and reliability.

-

Mechanical Strength: Graphite's layered composition grants it robust mechanical strength, ensuring longevity in rigorous conditions.

-

Chemical Inertness: Resistant to chemical reactions, graphite electrodes find a place in corrosive environments without deteriorating.

Manufacturing Excellence

-

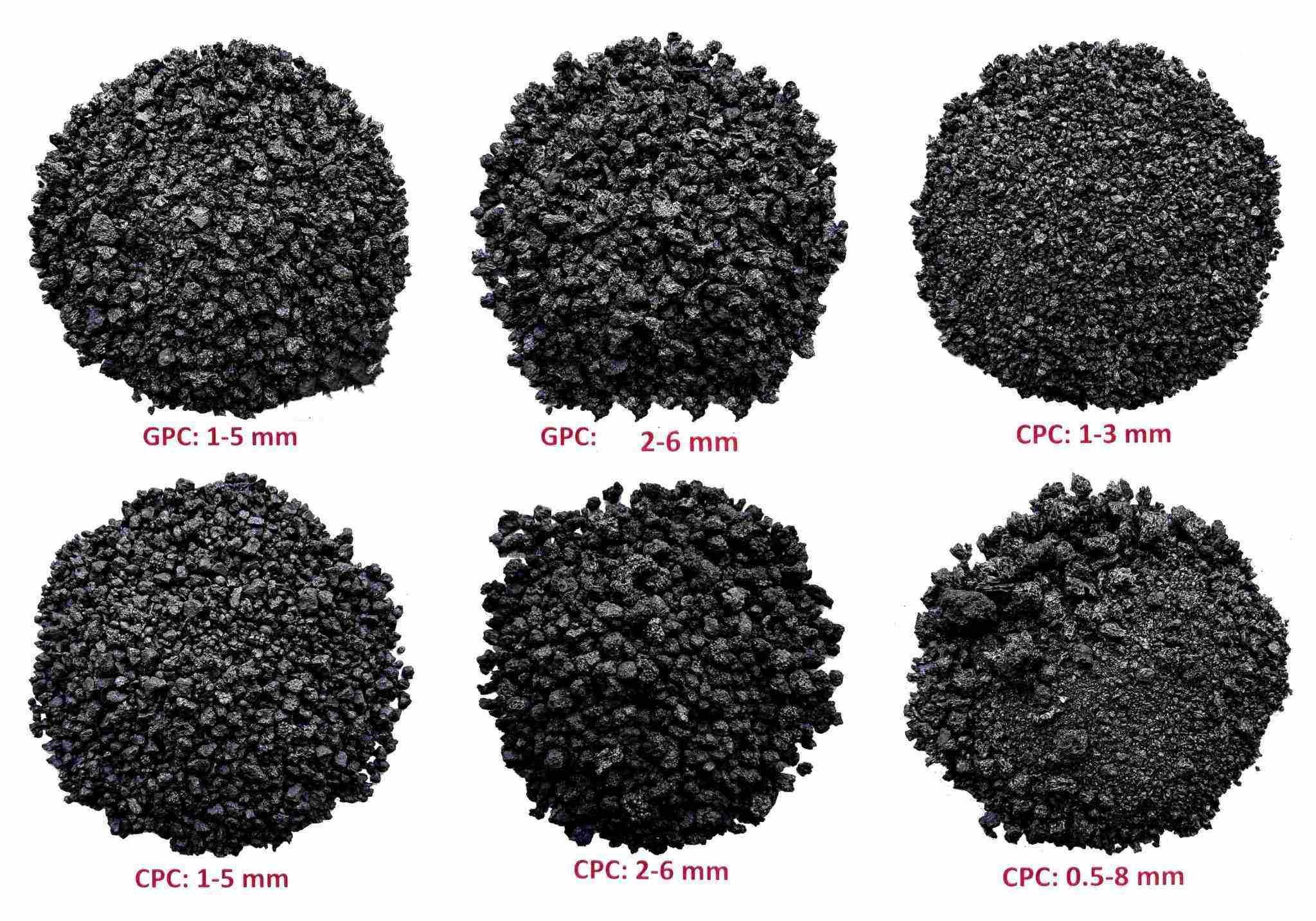

Raw Materials Selection: High-quality petroleum coke and needle coke serve as primary raw materials due to their low impurity content and desirable attributes.

-

Shaping and Forming: A blend of coke and binder pitch is shaped into electrodes, setting the stage for subsequent processes.

-

Baking: Oxygen-deprived heating eliminates volatile components and reinforces the structure's integrity.

-

Graphitization: Controlled high-temperature treatment induces graphitization, enhancing electrical conductivity.

-

Precision Finishing: Electrodes are machined to precise dimensions, ensuring compatibility with varied applications.

Diverse Applications

-

Metallurgy: Graphite electrodes play a crucial role in electric arc furnaces, generating the intense heat required for steel production. They aid in melting raw materials efficiently.

-

Energy Storage: Graphite electrodes are integral to lithium-ion batteries, offering efficient energy storage and release due to their ability to intercalate lithium ions.

-

Electrochemical Processes: Graphite's conductivity and chemical stability make it a staple in electrochemical applications such as electroplating and electro-winning.

-

Emerging Technologies: From aerospace to electronics, graphite electrodes find usage in cutting-edge industries, powering advancements in diverse fields.

Paving the Path to Progress

Graphite electrodes exemplify the fusion of material science and technological advancement. Their role in transforming industries, enabling energy-efficient processes, and driving innovation cannot be overstated. As industries continue to evolve, these electrodes are poised to be at the forefront, powering progress and shaping a brighter future.

RELEVANT INFORMATION