Welcome To Know Our Products, We Can Offer You High Quality Products!

WhatsApp : +8617736177359

Email : sales@fqcarbon.com

The Evolution of Calcined Petroleum Coke: From Raw Material to Industrial Marvel

2023-09-01

Calcined Petroleum Coke (CPC) has emerged as a linchpin in diverse industrial applications, driving efficiency and progress across sectors. This article embarks on a journey through the production, properties, and pivotal roles of CPC, shedding light on its significance.

The CPC Production Odyssey

Calcined Petroleum Coke undergoes a transformative process before taking center stage in various industries. Its production involves intricate steps that enhance its properties and usability.

1. Raw Material Selection: The journey begins with the selection of high-quality raw petroleum coke, extracted from crude oil refining. The composition of this starting material shapes the quality of the final CPC product.

2. Controlled Heating: The raw petroleum coke faces controlled heating in specialized furnaces, such as rotary kilns or vertical shaft furnaces. This process removes volatile components and triggers structural changes.

3. Structural Transformation: Under heat, the carbon atoms in the petroleum coke rearrange into a more graphitic structure, enhancing CPC's electrical conductivity and thermal stability.

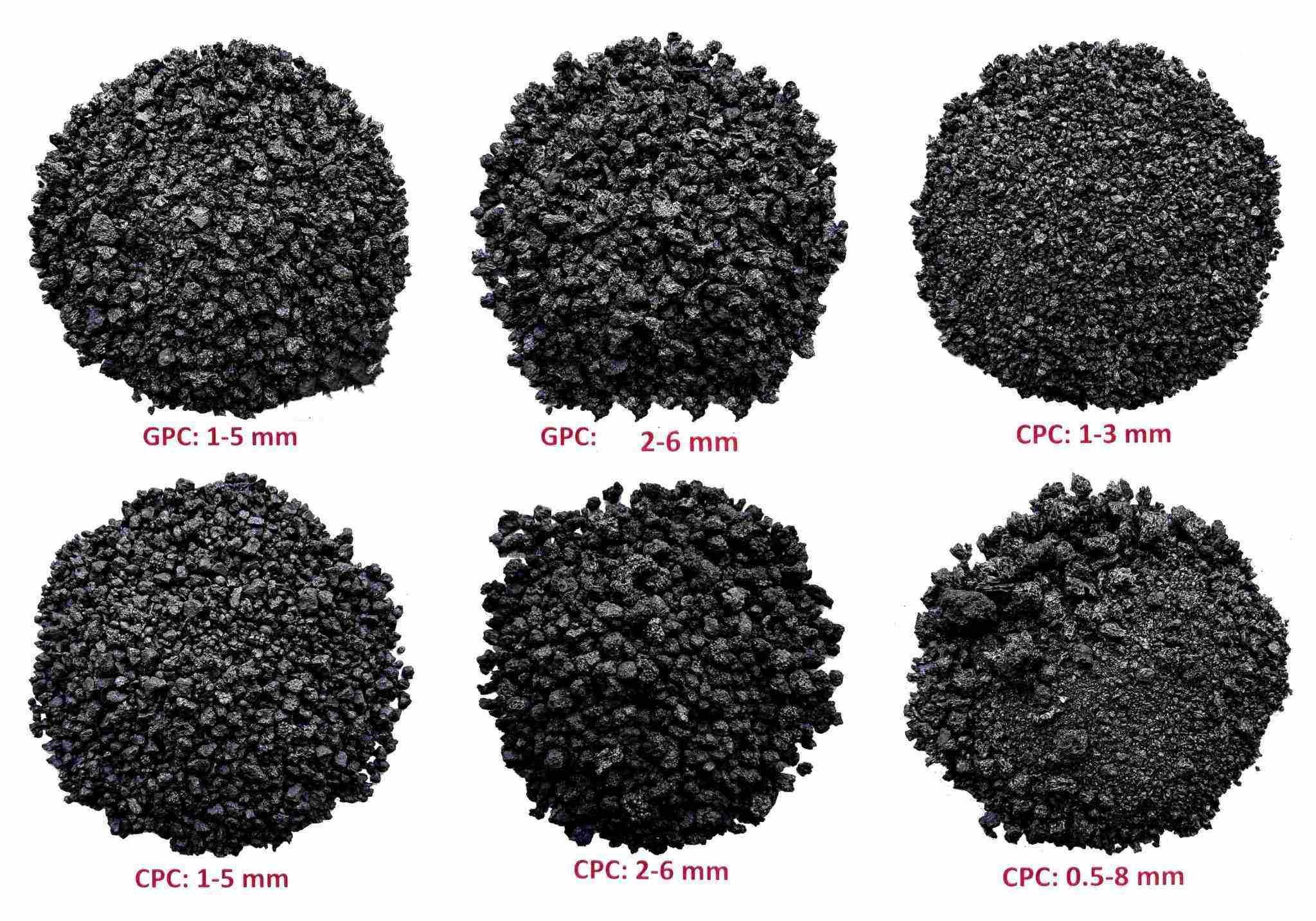

4. Sizing and Refining: The calcined product is carefully sized and refined to meet precise particle size distribution requirements, ensuring compatibility with a spectrum of applications.

Harnessing the Potential of Calcined Petroleum Coke

1. Metallurgical Marvel: In steel production, CPC becomes a crucial ingredient in electric arc furnaces, where its high carbon content fuels the heat necessary for melting raw materials into high-quality steel.

2. Aluminum Industry Backbone: CPC finds a home in the production of anodes used in aluminum smelting. Its carbon-rich nature facilitates efficient energy transfer, a cornerstone of the smelting process.

3. Fueling Energy Storage: As energy storage technologies flourish, CPC emerges as a key component in lithium-ion batteries. Its ability to intercalate lithium ions ensures efficient energy storage and release.

4. Catalyzing Electrochemical Processes: In electrochemical applications like fuel cells and electro-winning, CPC's excellent conductivity and stability make it an indispensable catalyst for energy-efficient processes.

Driving Innovation and Sustainability

1. Pioneering Sustainability: The utilization of CPC in energy-efficient processes aligns with the global push for sustainability, offering solutions to reduce carbon footprints and enhance operational efficacy.

2. Diverse Applications: Beyond its traditional applications, CPC's remarkable properties enable it to venture into new territories, such as aerospace and electronics, catalyzing advancements in diverse industries.

3. Shaping a Greener Future: As renewable energy gains momentum, CPC's role in energy storage and efficient processes positions it as a driver of the green energy revolution.

The Ongoing Evolution

From its humble origins as raw petroleum coke to its transformative journey into CPC, this material epitomizes the synergy between scientific innovation and industrial need. As industries strive for efficiency, sustainability, and technological progress, Calcined Petroleum Coke stands as a testament to human ingenuity and adaptability. Its pivotal roles in energy production, steelmaking, and emerging technologies showcase its versatility and enduring relevance in a rapidly evolving world.

RELEVANT INFORMATION