Welcome To Know Our Products, We Can Offer You High Quality Products!

WhatsApp : +8617736177359

Email : sales@fqcarbon.com

Unveiling the Transformation: The Significance of Calcined Petroleum Coke

2023-09-01

Calcined Petroleum Coke (CPC) stands as a crucial raw material that powers various industrial sectors, enabling processes and innovations that shape our world. This article dives into the realm of CPC, shedding light on its production process, unique properties, and diverse applications.

Decoding Calcined Petroleum Coke

Calcined Petroleum Coke is an essential element in industries that require high heat and electrical conductivity. With its distinct properties, CPC plays a pivotal role in multiple sectors, driving progress and efficiency.

The CPC Production Journey

-

Feedstock Selection: High-quality raw petroleum coke, derived from refining crude oil, serves as the initial material. Its composition and quality influence the final CPC product.

-

Heating Process: Raw petroleum coke undergoes a controlled heating process in a rotary kiln or vertical shaft furnace. This thermal treatment removes volatile components and transforms the coke's structure.

-

Graphitization: During the heating process, carbonization occurs, rearranging the carbon atoms into a more ordered and graphitic structure. This enhances CPC's conductivity and thermal stability.

-

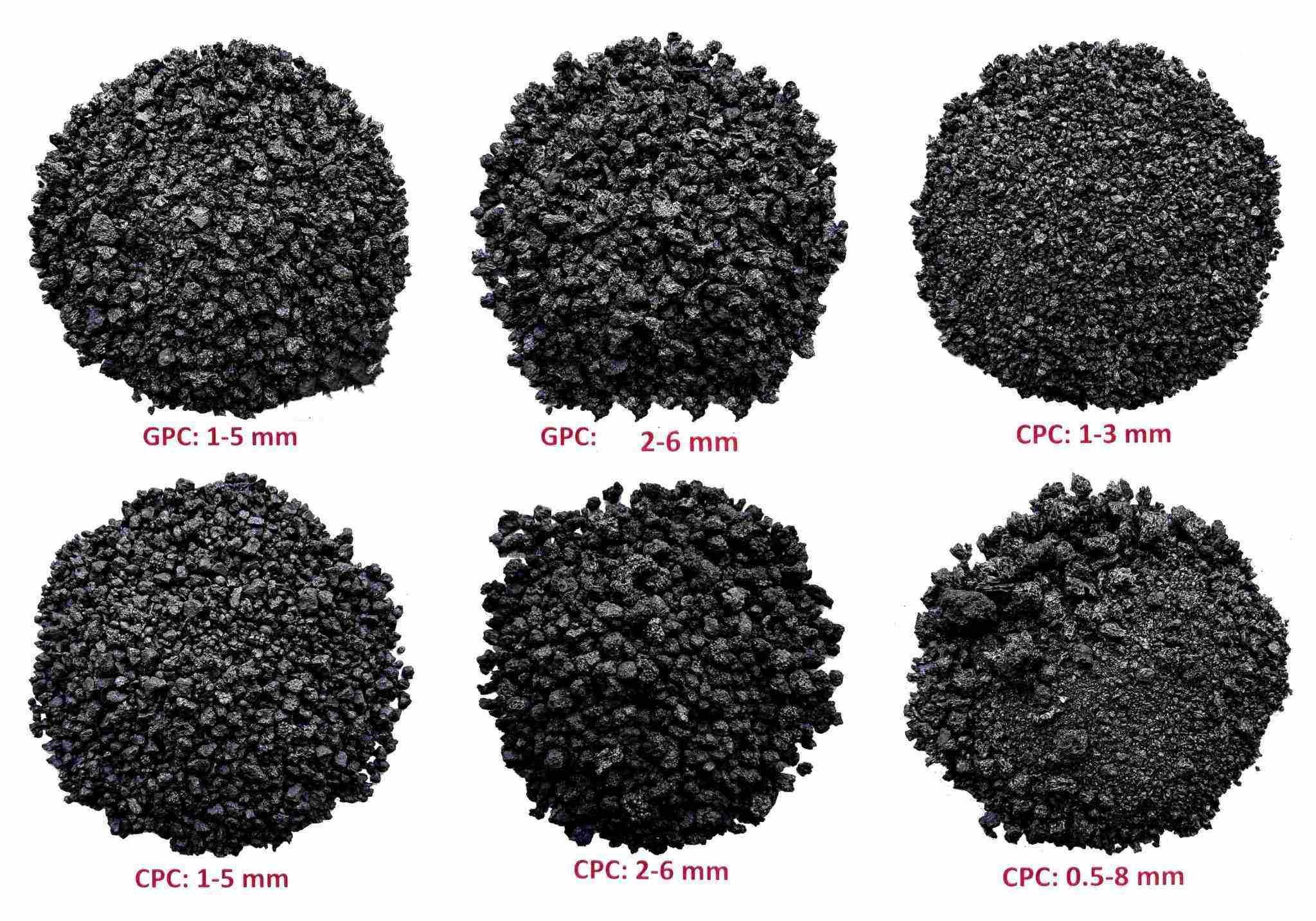

Sizing and Grinding: The calcined product is carefully sized and ground to meet specific particle size distribution requirements, catering to diverse applications.

The Power of Calcined Petroleum Coke

1. Efficient Energy Production: The aluminum industry relies on CPC to produce anodes for smelting. The carbon-rich nature of CPC makes it an ideal material for efficient energy transfer in the smelting process.

2. Steel Production: In electric arc furnaces, CPC acts as a key component in the production of high-quality steel. Its high carbon content aids in generating the intense heat required for melting raw materials.

3. Anode Material: CPC's conductivity and stability make it a preferred choice for manufacturing anodes used in various applications, including lithium-ion batteries and fuel cells.

4. Carbon Additive: In the metallurgical sector, CPC serves as a carbon additive, enhancing the carbon content of materials during the production of iron and steel.

Unlocking Potential Through Innovation

1. Energy Storage Revolution: Calcined Petroleum Coke's role in energy storage technologies, particularly in lithium-ion batteries, highlights its potential to shape the renewable energy landscape.

2. Sustainable Solutions: As industries strive for sustainability, CPC's use in energy-efficient processes contributes to reducing carbon footprints and enhancing operational efficiency.

3. Evolving Industrial Landscape: As technology advances, CPC finds new applications in emerging sectors like aerospace and electronics, where its properties contribute to groundbreaking innovations.

Conclusion

Calcined Petroleum Coke occupies a pivotal position in industries that require efficient energy transfer, high thermal stability, and exceptional electrical conductivity. From powering steel production to fueling the energy storage revolution, its diverse applications reflect its adaptability and significance. The transformation of raw petroleum coke into CPC showcases the intricate interplay between science and industry, creating a catalyst for innovation and progress. As we navigate toward a future defined by sustainability and technological advancement, Calcined Petroleum Coke's role continues to evolve, cementing its status as a cornerstone of modern industrial processes.

RELEVANT INFORMATION